Safety Relief Valves

Did you know Just Valves are an authorised reseller of VYC Industrial Valves?

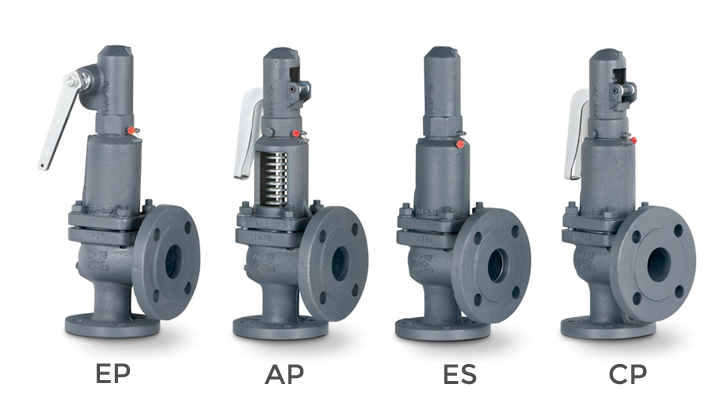

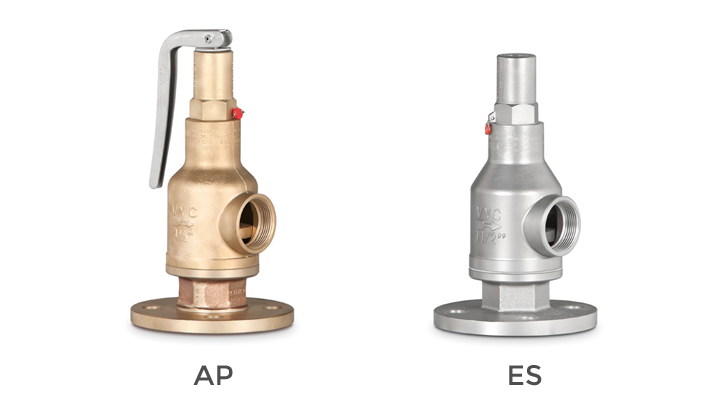

VYC Safety Relief Valves with elastomer sealing are available in a wide range to suit a multitude of applications. The available choice of body materials are Brass, Gun Metal, Modular Iron and Stainless Steel. Together with a wide range of elastomeric materials (viton standard) these valves are designed for pneumatic, gas, chemical and fluid carrying industrial applications. We offer both open and closed discharge types.

View our extensive range below…

Get in touch

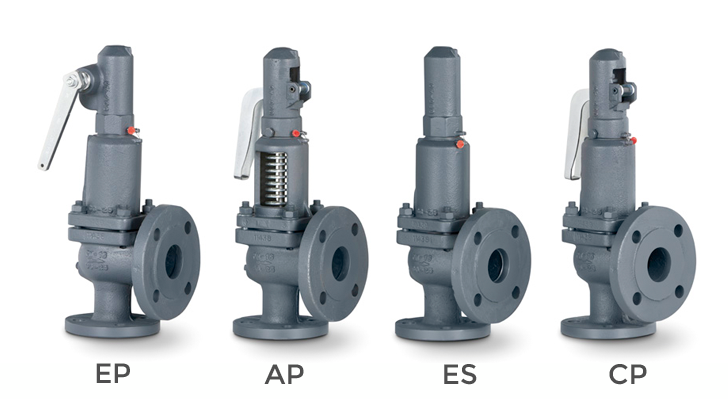

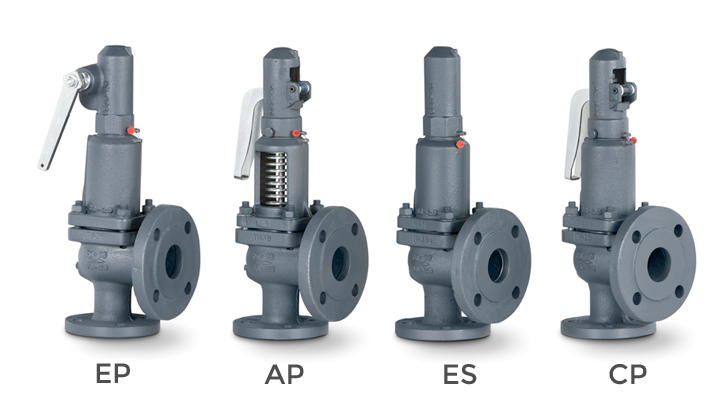

Full lift safety valve with spring loading (AIT) range

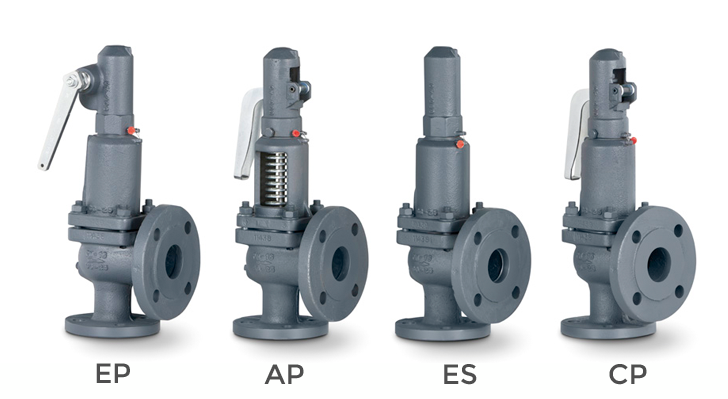

> MOD. 496 EN

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally. Design in accordance with “International Standard ISO 4126-1 Safety Valves”.

- Fabrication Program

- Catalogues by product

- Operating principles AP CP EP ES

- Assembly and disassembly instructions AP CP EP ES

- Complementary technical instructions

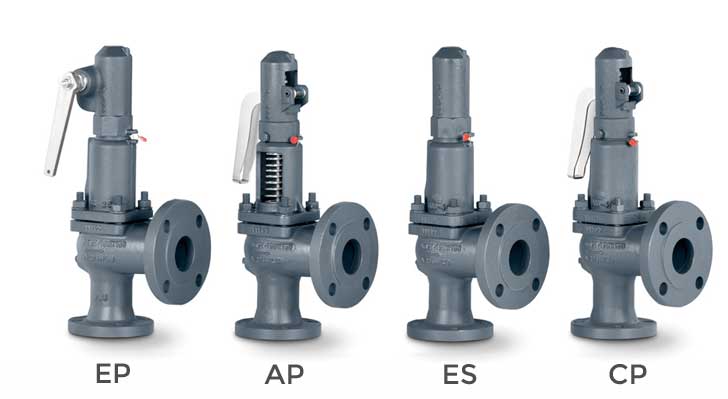

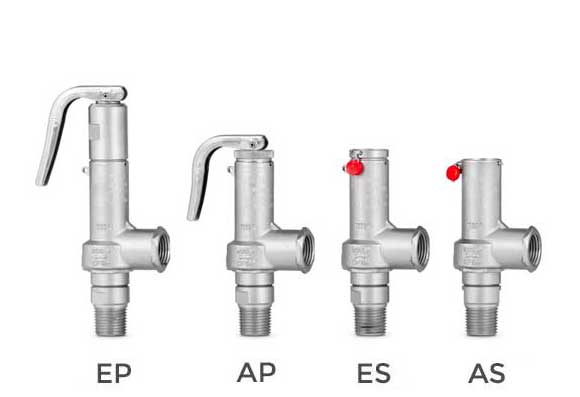

> MOD. 495 EN

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally. Design in accordance with “International Standard ISO 4126-1 Safety Valves”.

- Fabrication Program

- Catalogues by product

- Operating principles AP CP EP ES

- Assembly and disassembly instructions AP CP EP ES

- Complementary technical instructions

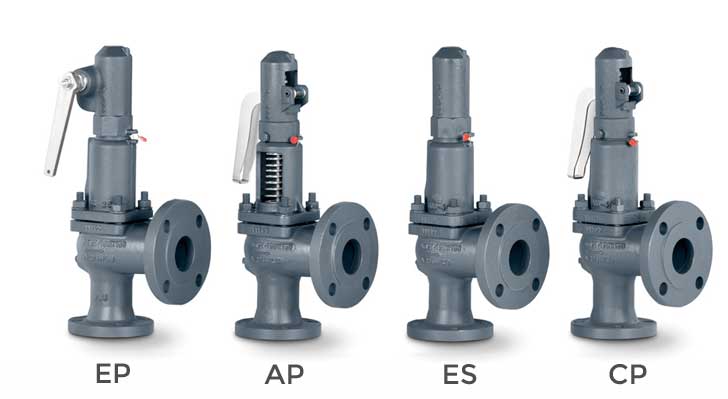

> MOD. 486 ASME

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally. Design in accordance with “ASME code section VIII Div.1”. Materials according ASME code section II and ASTM. Connections according ASME/ANSI B16.5 standard. Center to face dimensions according API-526.

- Fabrication Program

- Catalogues by product ANSI (SI) ANSI (USCS)

- Operating principles AP CP EP ES

- Assembly and disassembly instructions AP CP EP ES

- Complementary technical instructions

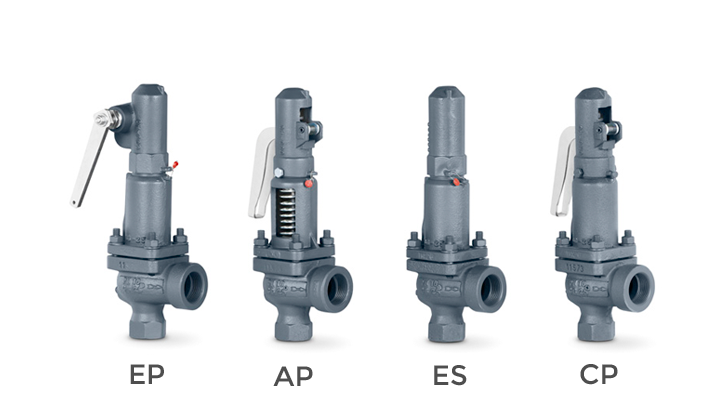

> MOD. 485 ASME

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally. Design in accordance with “ASME code section VIII Div.1”. Materials according ASME code section II and ASTM. Connections according ASME B1.20.1 standard.

- Fabrication program

- Catalogues by product NPT (SI) NPT (USCS)

- Operating principles AP CP EP ES

- Assembly and disassembly instructions AP CP EP ES

- Complementary technical instructions

> MOD. 596 EN

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally. Design in accordance with “International Standard ISO 4126-1 Safety Valves”.

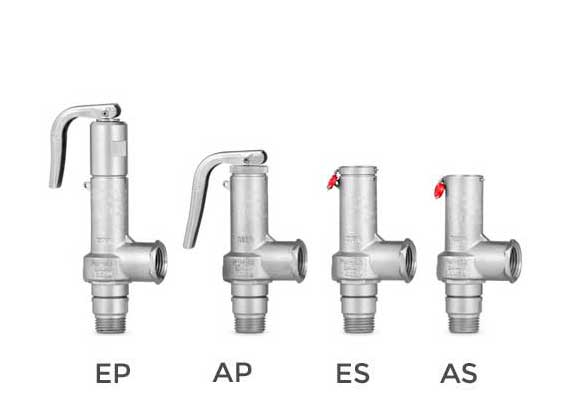

> MOD. 696 EN

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally. Design in accordance with “International Standard ISO 4126-1 Safety Valves”.

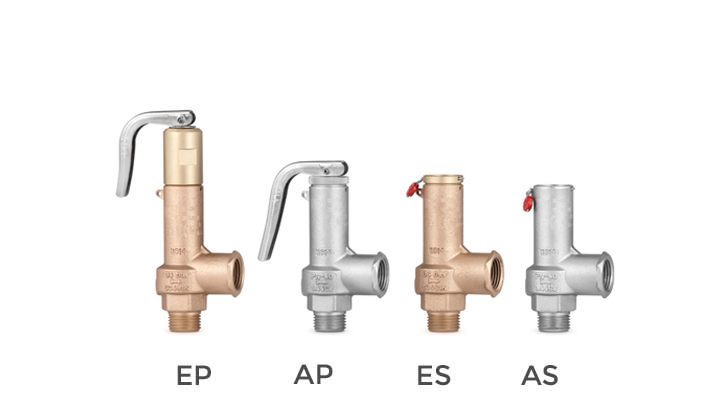

> MOD. 695 EN

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally. Design in accordance with “International Standard ISO 4126-1 Safety Valves”.

- Fabrication Program

- Catalogues by product

- Operating principles AP AS EP ES

- Assembly and disassembly instructions AP AS EP ES

- Complementary technical instructions

> MOD. 685 ASME

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally. Design in accordance with “ASME code section VIII Div.1”. Materials according ASME code section II and ASTM. Connections according ASME B1.20.1 standard.

- Fabrication Program

- Catalogues by product NPT (SI) NPT (USCS)

- Operating principles AP AS EP ES

- Complementary technical instructions

> MOD. 895 EN CRYOGENIC

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally. Design in accordance with “International Standard ISO 4126-1 Safety Valves”.

- Fabrication program

- Catalogues by product

- Operating principles AP AS EP ES

- Assembly and disassembly instructions AP AS

> MOD. 885 ASME CRYOGENIC

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally. Design in accordance with “ASME code section VIII Div.1”. Materials according ASME code section II and ASTM. Connections according ASME B1.20.1 standard.

- Fabrication program

- Catalogues by product NPT (SI) NPT (USCS)

- Operating principles AP AS EP ES

- Assembly and disassembly instructions AP AS EP ES

- Complementary technical instructions

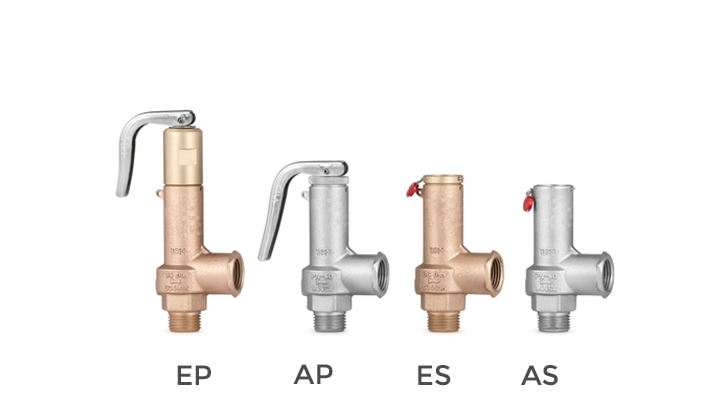

Full lift safety valve with spring loading (AIT) range

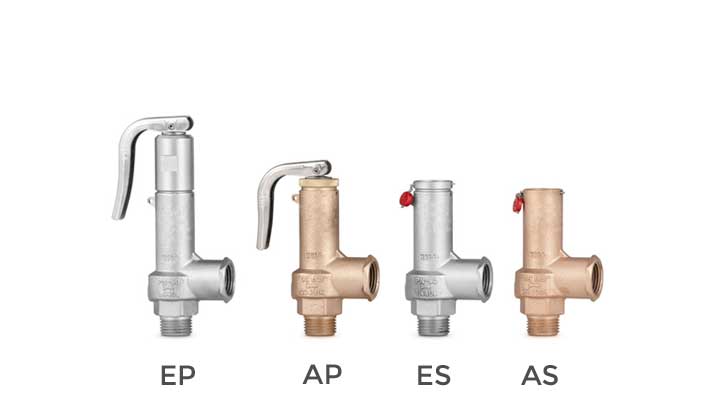

> MOD. 995 EN

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally. Design in accordance with “International Standard ISO 4126-1 Safety Valves”.

- Fabrication program

- Catalogues by product

- Operating principles AP AS EP ES

- Assembly and disassembly instructions AP ASEP ES

- Complementary technical instructions

> MOD. 985 ASME

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally. Design in accordance with “ASME code section VIII Div.1”. Materials according ASME code section II and ASTM. Connections according ASME B1.20.1 standard.

- Fabrication program

- Catalogues by product NPT (SI) NPT (USCS)

- Operating principles AP AS EP ES

- Assembly and disassembly instructions AP ASEP ES

- Complementary technical instructions

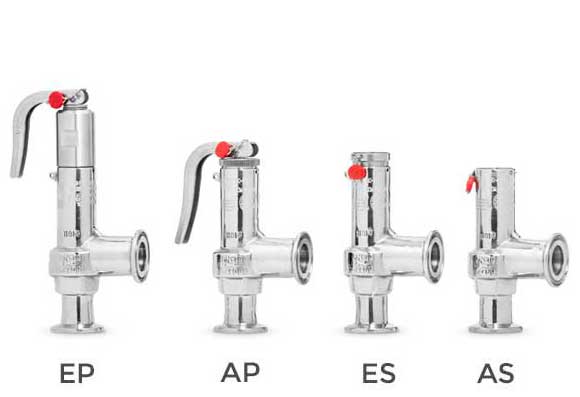

> MOD. 694 CLAMP

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally. Design in accordance with “ASME code section VIII Div.1”. Materials according ASME code section II and ASTM. Connections according ASME ISO 2852 standard.

- Fabrication program

- Catalogues by product

- Operating principles AP AS EP ES

- Assembly and disassembly instructions AP ASEP ES

- Complementary technical instructions

Normal safety valve (AN)

> MOD. 494 EN

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open, at the fi rst proportional to the pressure increase, and after instantly and totally. Design in accordance with “International Standard ISO 4126 -1 Safety Valves”.

- Fabrication program

- Catalogues by product

- Operating principles AP CP EP ES

- Assembly and disassembly instructions AP CP EP ES

- Complementary technical instructions

> MOD. 004

Controlled safety pressure relief system CSPRS valves are mainly used where conventional direct-loaded spring action valves cannot guarantee the opening and closing margins that certain specifi c conditions of service demand. The objective is to help the closure by means of pressure so that the valve remains completely watertight until reaching the set pressure and/or to activate the opening with pressure. Once evacuated and in keeping with a previous adjustment, to assist with closing pressure, to once again achieve closure with the desired watertightness. This allows us to:

- Stabilise the functioning in critical applications of one or several valves.

- Improve performance, position, repeatability and operational effi ciency.

- Improve the opening-closure hysteresis.

- Reduce product losses and minimise them in the case of working with several valves at staggered pressures, if conditions so permit.

- Increase the operating pressure of the system up to 99.9% of the set pressure.The control safety pressure relief system CSPRS device can be used with any safety valve available in the market and in particular, with models VYC Mod. 485, 486, 494, 495 and 496.

Normal safety valve with spring loading (AN) range

> MOD. 295 EN

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open, at the fi rst proportional to the pressure increase, and after instantly and totally. Design in accordance with “International Standard ISO 4126 -1 Safety Valves”.

- Fabrication program

- Catalogues by product

- Operating principles AP ES

- Assembly and disassembly instructions AP ES

- Complementary technical instructions

> MOD. 296 EN

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open, at the fi rst proportional to the pressure increase, and after instantly and totally. Design in accordance with “International Standard ISO 4126 -1 Safety Valves”.

- Fabrication program

- Catalogues by product

- Operating principles AP ES

- Assembly and disassembly instructions AP ES

- Complementary technical instructions

Proportional safety valve with spring loading (AP) range

> MOD. 095 EN

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open proportional to the pressure increase. Design in accordance with “International Standard ISO 4126-1 Safety Valves”.

- Fabrication program

- Catalogues by product

- Operating principles AP ES

- Assembly and disassembly instructions AP ES

- Complementary technical instructions

> MOD. 096 EN

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open proportional to the pressure increase. Design in accordance with “International Standard ISO 4126-1 Safety Valves”

- Fabrication program

- Catalogues by product

- Operating principles AP ES

- Assembly and disassembly AP ES

- Complementary technical instructions

Vacuum breaker safety valve range

> MOD. 795 EN

The valve acts as an automatic regulator of pressure drops and prevents the creation of a vacuum inside pressurised installations or vessels.

> MOD. 785 ASME

The valve acts as an automatic regulator of pressure drops and prevents the creation of a vacuum inside pressurised installations or vessels.

Multi-stage diffusion silencers

![VYC0051[1]](https://www.justvalves.com.au/wp-content/uploads/2021/06/VYC00511.png)

> MOD.005 EN ASME/ANSI ASME/FNPT ASME/MNPT ASME/SW

During the expansion process for compressible substances such as gases, steam or air, one of the main problems is noise pollution. The noise is caused by opening the valve and discharging the expanded fluid at the speed of sound. Silencers are a great way to reduce this noise, caused by discharging the valve, bringing it down to allowable levels. They are used in places such as power, chemical and petrochemical plants to discharge safety valves, control valves, etc. in pressure lines and equipment that convey compressible substances such as steam, air, carbon dioxide, helium, methane, nitrogen, oxygen and other gases. They achieve noise reductions of more than 50 dB without any additional acoustic absorption materials.

Test bench for safety valves DN10 – 125 / ¼” – 5”

>Test bench for safety valves DN10 – 125 / ¼” – 5”

The test bench allows testing all types of safety valves up to DN125 / 5” according to international standards. It is suitable for those companies trading with safety valves. The test system contains:

- Pressure regulator 1,6 – 276 bar (Maximum input 210 bar)

- Insulation valve

- Relief valve

- Pressure gauge EN-837-1 ø150, 16bar, Cl.0,5

- Pressure gauge EN-837-1 ø150, 160bar, Cl.0,5

- Pressure gauge EN-837-1 ø150, 250bar, Cl.1,6

![VYC295[1]](https://www.justvalves.com.au/wp-content/uploads/2021/06/VYC2951.png)

![VYC296[1]](https://www.justvalves.com.au/wp-content/uploads/2021/06/VYC2961.jpg)

![VYC095[1]](https://www.justvalves.com.au/wp-content/uploads/2021/06/VYC0951.png)

![VYCbanco-pruebas-seguridad-valvulas-3[1]](https://www.justvalves.com.au/wp-content/uploads/2021/06/VYCbanco-pruebas-seguridad-valvulas-31.jpg)